The Transcend Design Generator (TDG) now has the capability to design facilities with biological phosphorus removal!

We’d like to highlight some details about the background calculations – this is going to be the first post of our “What’s in the black-box?” series.

This new feature in TDG covers mainstream biological phosphorus removal. The design process can be separated into two steps:

- The first is an initial calculation using spreadsheet-based methods available in public literature to define proper reactor volumes, recirculation ratios, and so on.

- The second step is verification with process simulation. If simulation results indicate that with the initially calculated volumes of ratios and recycle flows that the system cannot meet the effluent criteria, process parameters are adjusted and the simulation runs again, up until the effluent concentrations are below the target values.

So how Bio-P get incorporated into this structure?

Conventional design procedures claim that 1-2 hours of anaerobic retention time is sufficient for achieving biological phosphorus removal. This design principle was followed for many years, which led to a situation where the common knowledge among engineers was that it was hard to operate Bio-P plants and these facilities often failed to perform as a Bio-P plant.

However, recent findings (Dold, 2019) highlighted that most of these facilities simply did not have enough anaerobic mass to provide proper conditions for the growth of PAOs (phosphorus accumulating organisms). To avoid undersizing, TDG follows the guidelines from Dold (2019) where about 15-25% anaerobic mass fraction is required to achieve proper and stable biological phosphorus removal.

On the modeling side, two new biomass groups were added to the model – PAO (Phosphorus Accumulating Organism) and GAO (Glycogen Accumulating Organisms). It is worth adding both, as GAOs compete with PAOs for the substrate – the only difference is that GAOs do not do luxury P uptake, so they do not take part in the phosphorus removal just consume the substrate. It is important to have PAOs and not GAOs in the facility if proper Bio-P performance has to be achieved.

What about the details in terms of the target 15-25% anaerobic mass fraction to be designed?

Based on the data from Dold et al. (2019) a curve was developed for defining the anaerobic mass fraction target value as a function of the ratio of total phosphorus to be removed and available influent COD (Figure 1).

Figure 1. Dataset used for developing curve to define target anaerobic mass fraction

The curve clearly states that as more TP is to be removed, higher mass fractions are required, and as the influent COD decreases, also the anaerobic mass fraction increment is necessary so the favorable organisms can grow without any disruption.

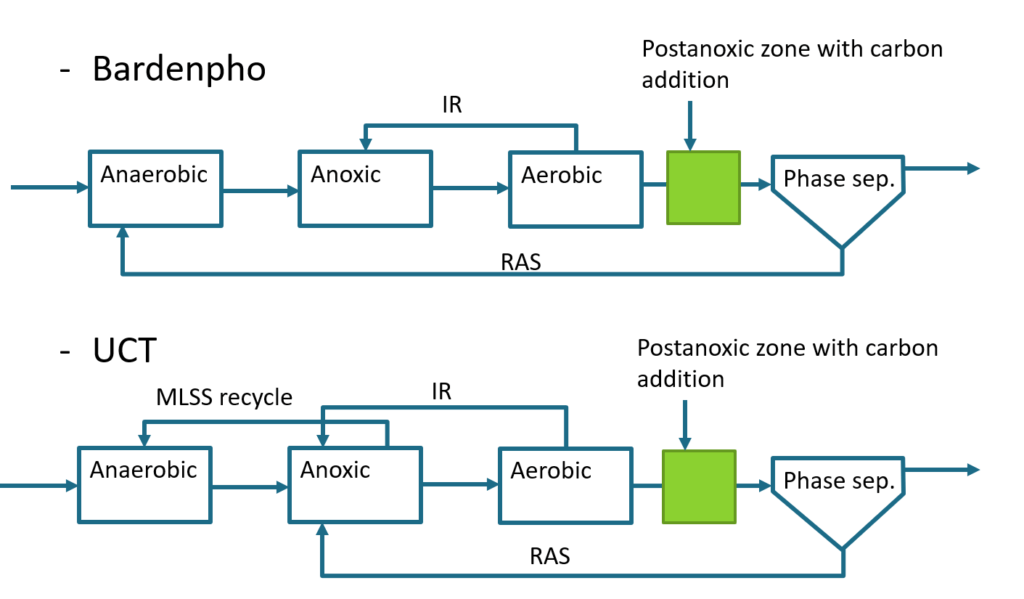

Figure 2. Supported configurations in TDG

TDG supports two mainstream configurations for biological phosphorus removal – Bardenpho (also known as A2/O) and UCT (Fig. 2).

Most of the cases UCT is considered a more stable process as the nitrate is not directed back to the anaerobic zone with RAS (as it happens in case of A2/O). However, UCT has lower MLSS in the anaerobic zone, as a separate MLSS recycle has to be operated to keep the desired MLSS level, which leads to a higher reactor volume especially if the design is driven by the overall anaerobic mass fraction.

Both configurations can have a postanoxic zone for low TN cases.

TDG is designed to enhance optioneering tasks – it is quite easy to assess different options like Bardenpho or UCT configurations for a Bio-P version, a simple configuration with chemical P removal only, versions with/without primary clarifiers – and engineers just need to evaluate the results (e.g., total reactor volume, OPEX, energy consumption, chemical demand, etc.) and make decisions – without having the full design procedure to be done for all options.

References

Dold, P., Conidi, D. (2019). Enhanced Biological P Removal: Have we forgotten how to design a bioP plant? Proceedings of the Water Environment Federation, WEFTEC 2019.